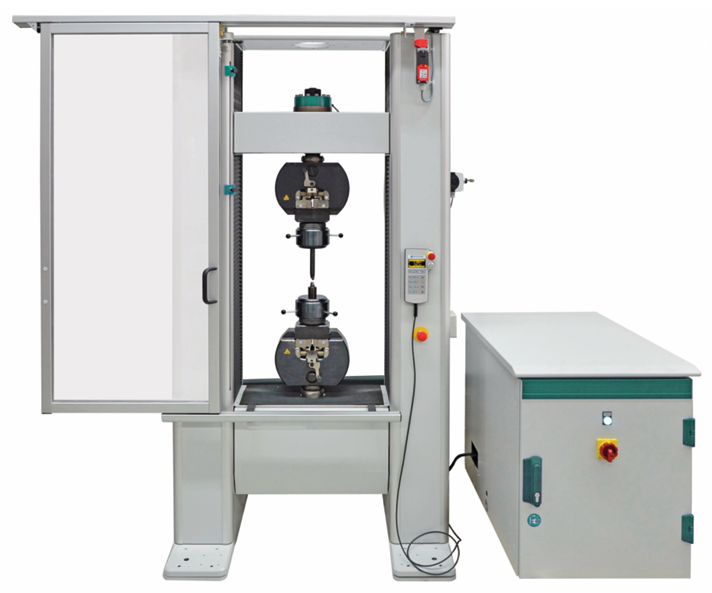

Universal Testing Machines

ST 250 kN – Universal Testing Machine for High Load Applications

The ST 250 kN universal testing machine from Richard Hess MBV GmbH is designed for precise, standards-compliant material and component testing in the medium to high load range.

Whether in quality assurance, test laboratories, or industrial environments – this robust system stands out through:

- outstanding frame stiffness

- advanced drive technology

- user-friendly test software

The high-performance solution for standardized tensile, compression, bending, and peel tests.

Precise. Versatile. Reliable.

Robust & Flexible Load Frame – For Demanding Testing Tasks

The modular load frame concept of the ST 250 kN ensures maximum stability and flexibility – ideal for frequently changing test setups and various specimen geometries.

Flexibility through modular frame design:

- Equipped with two vertical test spaces as standard, optional lateral test space

- Variable frame heights and widths – adaptable to individual applications

- Easy integration of peripheral devices (e.g. temperature chambers, furnaces, extensometers, optical sensors)

High-Precision Mechanics – For Reliable Results

- Four guide columns and two backlash-free precision ball screws

- Preloaded guides and rugged construction with bellows covers

- Designed for use in demanding production environments

- Brushless AC drive with Harmonic Drive® technology for:

- Precise, low-backlash force transmission

- High testing speeds

- Long-term and cyclic loading applications

Intelligent Control Electronics – For Maximum Accuracy

The ST 250 kN is equipped with cutting-edge adaptive control electronics, offering high system resolution and extensive control options.

Modular control unit with:

- Adaptive controller for dynamic parameter adjustment

- High-resolution signal converters for detailed analysis

- Integrated standard features including:

- Force, displacement, and strain control

- Overload protection

- Automatic sensor identification incl. calibration data

- Specimen break detection

- Return-to-start function

- Manual positioning via test software or optional handheld control device

Safety & Efficiency in Daily Use

- CE-compliant safety enclosure – optional for all machine configurations

- Stable design with vibration-damping feet – no foundation required

- Future-proof & scalable – thanks to modular expandability

Perfectly Matched: Test Software by Richard Hess MBV GmbH

The ST 250 kN is fully compatible with the powerful test software from Richard Hess MBV GmbH:

- Includes all standard modules (tensile, compression, bending, peel)

- Supports both simple and complex test sequences – standard-compliant or customized

- High flexibility in device integration, data import/export, and test sequence configuration

Conclusion:

The ST 250 kN universal testing machine delivers maximum performance, reliability, and flexibility for demanding testing applications in the high-load segment – ideal for today’s needs and tomorrow’s challenges in material testing.

Technical Data – ST 250 kN

| Specification | Value |

|---|---|

| Nominal Load (Main Test Area) | 250 kN |

| Test Area Above Crosshead | 3 kN |

| Mechanical Design | 2 backlash-free precision ball screws, 4 hardened guide columns with spindle protection, AC servo drive |

| Frame Stiffness | 260 kN/mm (including deformation of load cell and adapter) |

| Test Speed | 0.00006 – 600 mm/min (optionally expandable) |

| Crosshead Travel Resolution | < 0.0012 µm |

| Force Measurement Range | 0.1 – 100 % of nominal load, Class 1 (optional Class 0.5), according to DIN EN ISO 7500-1 / ASTM E4 |

| Measurement, Control & Regulation | Integrated force and crosshead channels, 3 free slots (expandable to 7) |

| Data Transmission | Ethernet (LAN) or USB, 50 Hz (standard), higher frequency optional |

| Power Supply | 3P/PE/400 V, 50 Hz (TN system), 4.0 kW, 4 m cable with 16CEE plug on control unit |

| Environmental Conditions | Temperature: 5–40 °C, Humidity: 20–80 % |

| Tool Holder Interface | R60/30 or LK135-12xM12-IG |

| Included in Delivery | Testing machine incl. measurement and control electronics, handheld device with force/displacement display |

| Required for Operation | Load cell, grips/test tools, adapter set, test software, PC (current standard), Windows OS |

Optional Extensions – ST 250 kN

- Temperature control systems (e.g. ovens, climate chambers)

- Extensometers: clip-on, long-travel, optical

- Safety enclosures (CE-compliant)

- Additional test areas: lateral or above the crosshead

- Increased test speed (optional)

Modified crosshead:

- Movable load cell mount (for off-axis testing)

- Multi-load cell setup possible

Accessories:

- T-slot plates, adapters, specimen holders, and more

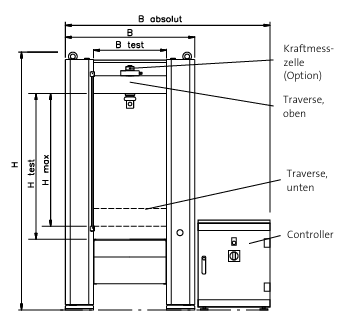

Dimensions / Weight – ST 250 kN

| Specification | Value |

|---|---|

| H (Total height) | 2150 mm |

| H test (Test space height) | 1200 mm |

| H max (Max. crosshead travel without tools, adapter, or load cell) | 1070 mm |

| B (Width) | 1080 mm |

| B total (Including controller unit) | approx. 1700 mm |

| B test (Test space width) | 610 mm |

| T (Depth) | 700 mm |

| Weight | 1100 kg |