LabVac Series

Automated vacuum presses for precise material testing under controlled atmospheres

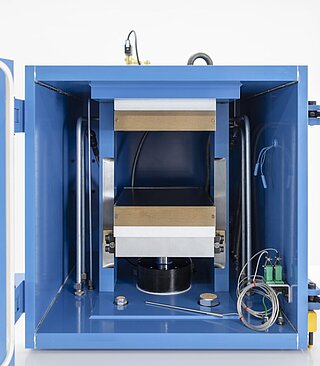

The Fontijne Presses LabVac Series – available with press forces of 50 kN, 200 kN, 400 kN, 600 kN or 1000 kN – is a fully automated hydraulic laboratory press equipped with an integrated vacuum chamber.

It is designed for applications requiring materials to be processed or tested under vacuum or inert gas conditions, such as oxygen-free environments or atmospheres using nitrogen or argon.

Like all Fontijne Presses products, the LabVac Series is renowned for its consistent, precise, and reproducible pressing quality – regardless of the selected model or process parameters.

Depending on the configuration, the LabVac offers pressing forces up to 1000 kN and temperatures up to 300 °C, making it ideal for demanding quality control (QC) and research & development (R&D) applications involving advanced materials and composites.

The integrated vacuum pump creates a low-pressure environment of 30–40 mbar inside the press chamber.

This enables testing and molding processes without oxygen or with alternative process gases.

A rear air outlet allows the system to be connected to an external exhaust or filtration system, ensuring that air and gases are safely removed from the chamber.

Every LabVac press is equipped with our advanced ProView control system, featuring a 15-inch touchscreen for precise management of pressure, temperature, and vacuum parameters.

The vacuum system can be operated manually via the control panel or automatically as part of a stored recipe. After pressing, the chamber can be rapidly vented with air for quick sample access.

The large, clear ProView display provides operators with a comprehensive overview of all process data and trends, ensuring maximum ease of use and process transparency.

Thanks to its compact footprint, the LabVac can be easily integrated into any laboratory environment.

Its robust construction, high-quality components, and reliable control system ensure long-term precision and durability, even in intensive laboratory use.

👉 Contact us – we’ll be happy to help you find the ideal solution for your testing needs.

Options – LabVac Series

| Option | Description |

|---|---|

| Active Cooling System | Automated water-cooling of the press plates, controlled by electric valves. This allows the press to be quickly prepared for subsequent tasks that require a lower temperature setpoint. |

| Argon/Nitrogen Connection | Connection port for operating the press under inert gases such as argon or nitrogen. |

| Light and Sound Signal | An integrated optical and acoustic signal indicates the current status of the press cycle. |

| Ethernet Connection | For easy data transfer and export of process parameters. |

| External Thermocouple Connection | Allows external temperature readings to be integrated into the process sequence via the ProView control system. |

| Fast Heating System | With the fast heating system, the LabVac press can achieve a heating rate of up to 20 °C per minute. This significantly reduces heating time — for example, 180 °C is reached in only 8 minutes (instead of 16) and 300 °C in 14 minutes (instead of 28). |

| Steel, Aluminum, or Copper Plates | Optional plates made of steel, aluminum, or copper can be used to achieve specific temperature distribution profiles — depending on the material and application. |

| Extended Warranty & Maintenance Plan | The standard warranty can be extended upon request. Fontijne Presses also offers preventive maintenance and calibration services to ensure long-term precision and reliability. |

| Custom Design | Need different temperatures, closing forces, or plate sizes? Share your specific requirements with us — we will develop a custom-made solution tailored precisely to your application. |

Technical Specifications – LabVac Series

| Model | LabVac 50 | LabVac 200 | LabVac 400 | LabVac 600 | LabVac 1000 |

|---|---|---|---|---|---|

| Maximum closing force * | 50 kN | 200 kN | 400 kN | 600 kN | 1000 kN |

| Plate size * | 225 × 225 mm | 225 × 320 mm | 320 × 320 mm | 400 × 400 mm | 500 × 500 mm |

| Specific pressure at full load | 0.99 N/mm² | 2.78 N/mm² | 3.91 N/mm² | 3.75 N/mm² | 4 N/mm² |

| Maximum temperature * | colspan=5 | 300 °C | |||

| Daylight opening * | colspan=5 | 200 mm | |||

| Current rating | 16 A | 16 A | 16 A | 32 A | 32 A |

| Voltage | colspan=5 | 400 V – 3 phase – 50 Hz + neutral + earth 480 V – 3 phase – 60 Hz + neutral + earth | |||

| Length | 1360 mm | colspan=4 | 1540 mm | ||

| Width | 675 mm | colspan=4 | 810 mm | ||

| Height | colspan=5 | 1685 mm | |||

| Weight | 1160 kg | 1250 kg | 1300 kg | 1875 kg | 2150 kg |

* Depending on configuration and selected options.