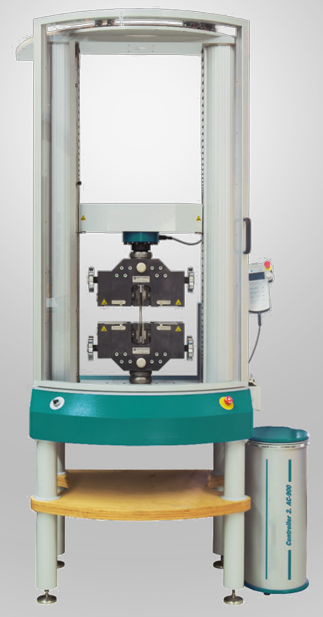

Universal Testing Machines

H5-H50 TMCI / H100-H250 TMCI – Versatile Testing Performance for the Medium Load Range

The H5-H50 TMCI and H50-H250 TMCI universal testing machines from Richard Hess MBV GmbH are engineered for precise and standards-compliant material and component testing in the medium load range. Whether in quality assurance, laboratories, or production environments, these high-performance systems stand out with:

- Modular flexibility

- State-of-the-art drive technology

- User-friendly design

The professional solution for standard-compliant tensile, compression, bending, and peel testing.

Reliable. Powerful. Modular.

Modern & Flexible Load Frame Design – For a Wide Range of Test Requirements

The frame design combines maximum precision with outstanding adaptability, making it ideal for changing setups in research, development, and industrial testing environments.

Versatility through Modular Frame Construction

- Adjustable in height and width → perfect for adapting to various specimen and component geometries

- Easy integration of peripheral devices (e.g. furnaces, temperature chambers, extensometers, displacement sensors, optical systems)

Maximum Measurement Precision Thanks to Innovative Mechanics

- Backlash-free precision ball screws with large diameters

- Preloaded aluminum support profiles and special nut system ensure:

- Accurate force transmission

- High lateral force stability

- Increased axial stiffness

- Brushless AC drive – ideal for static testing, cyclic loading, and long-term durability tests

Adaptive Control Electronics – For Maximum Resolution & Functionality

- Modular design with high control accuracy

- Integrated adaptive controller

- High-resolution signal converters for capturing fine details

Comprehensive Standard Features:

- Force-, displacement-, and strain-controlled operation

- Overload protection

- Automatic sensor identification including calibration data storage

- Specimen break detection

- Return-to-start function

- Manual positioning via optional handheld control or testing software

Safety & User Comfort at the Highest Level

- CE-compliant safety enclosures – optional for all applications

- Future-proof and upgradeable – scalable to meet specific needs and budgets

The Result:

A high-performance testing frame that combines precision, modular adaptability, and operator convenience – ideal for current and future testing challenges in materials and component testing.

H5 - H50 TMCI

Technical Data

| Nominal Load | 5 kN | 10 kN | 20 kN |

| Frame Stiffness | 10 kN/mm (including deformation of load cell and fixture adapter) | 18 kN/mm (including deformation of load cell and fixture adapter) | 40 kN/mm (including deformation of load cell and fixture adapter) |

| Specification | Value |

|---|---|

| Mechanical Design | 2 backlash-free precision ball screws with spindle protection |

| Drive System | AC servo motor |

| Testing Speed | 0.005 – 2000 mm/min (optionally expandable) |

| Crosshead Travel Resolution | < 0.01 µm |

| Force Measurement Range | Class 1 (optional Class 0.5), 0.1 – 100 % of nominal load depending on the load cell used (per DIN EN ISO 7500-1, ASTM E4) |

| Force Measurement Resolution | 24 bit (±8,388,608 digits) |

| Measurement, Control & Regulation Electronics | Integrated force and travel channels, 3 free slots for analog/digital I/Os, optionally expandable to 7 slots |

| Data Interface | Ethernet (LAN) or USB, 50 Hz (standard), higher data acquisition rates optional |

| Power Supply | 230 VAC, 0.7 kVA, 50/60 Hz, operating temperature: 5 – 40 °C, humidity: 20 – 80 % |

| Main Tool Mounting Interface | R20/8 |

| Required Options for Operation | Handheld controller with force/displacement display, load cell, test grips/tools, adapter set, software, PC (current standard), Windows® OS |

Additional Options

Customize your testing machine to meet your specific requirements with the following optional accessories:

Accessories & System Extensions

- Base frame table for conversion into a floor-standing model (standard height: 685 mm)

- Temperature control devices – e.g. furnaces, temperature chambers

- Extensometers – clip-on, long-travel, and optical systems

- Safety enclosures – CE-compliant and configurable

- T-slot plates – ideal for component testing setups

- Electronics expansion – from 3 up to 7 slots for I/O modules

- Extended testing speed – for dynamic or time-sensitive applications

Special Crosshead Options

- Modified moving crosshead:

- with load cell shift unit for off-axis testing

- for mounting multiple load cells side by side

- with through-hole for guide bushings, e.g. for spring compression tools

- Lower fixed crosshead with through-hole

- for testing beneath the load frame

Technical Data – 50 kN Testing Machine

| Specification | Value |

|---|---|

| Nominal Load | 50 kN |

| Mechanical Design | 2 backlash-free precision ball screws with spindle protection |

| Drive System | AC servo motor |

| Frame Stiffness | 68 kN/mm (including deformation of load cell and tool adapter) |

| Testing Speed | 0.001 – 800 mm/min (optionally expandable) |

| Crosshead Travel Resolution | < 0.005 µm |

| Force Measurement Range | Class 1 (optional Class 0.5), 0.1 – 100 % of nominal load depending on load cell (per DIN EN ISO 7500-1, ASTM E4) |

| Force Measurement Resolution | 24 bit (±8,388,608 digits) |

| Measurement, Control & Regulation Electronics | Integrated force and travel channels, 3 free slots for analog/digital I/Os, expandable to 7 slots (optional) |

| Data Interface | Ethernet (LAN) or USB, 50 Hz (standard), optional higher acquisition frequency |

| Power Supply | 230 VAC, 1.5 kVA, 50/60 Hz, operating temperature: 5 – 40 °C, humidity: 20 – 80 % |

| Main Tool Mount Interface | R36/18 |

| Required Options for Operation | Handheld controller with force/travel display, load cell, test fixtures/tools, adapter set, software, PC (current standard), Windows® OS |

Optional Accessories

Our testing machines can be flexibly adapted to your needs:

- Base table (standard height 685 mm) – converts to a floor-standing model

- Temperature control devices – e.g. furnaces, climate chambers

- Extensometers – clip-on, long-travel, optical systems

- Safety enclosures – CE-compliant

- T-slot plates – ideal for component testing setups

- Electronics expansion – up to 7 available slots

- Increased testing speed – optional upgrade

Traverse & Frame – Special Options

- Modified moving crosshead

- with load cell positioning unit

- for mounting multiple load cells

- with through-hole for guide bushings (e.g. for spring compression testing)

- Lower fixed crosshead with through-hole

- enables testing below the load frame

Technical Data – 100 kN Testing Machine

| Specification | Value |

|---|---|

| Nominal Load | 100 kN |

| Mechanical Design | 2 backlash-free precision ball screws with spindle protection |

| Drive System | AC servo motor |

| Frame Stiffness | 120 kN/mm (including deformation of load cell and tool adapter) |

| Testing Speed | 0.0005 – 400 mm/min (optionally expandable) |

| Crosshead Travel Resolution | < 0.0025 µm |

| Force Measurement Range | Class 1 (optional Class 0.5), 0.1 – 100 % of nominal load depending on the load cell used (per DIN EN ISO 7500-1, ASTM E4) |

| Force Measurement Resolution | 24 bit (±8,388,608 digits) |

| Measurement, Control & Regulation Electronics | Integrated force and travel channels, 3 free slots for analog/digital I/Os, optionally expandable to 7 slots |

| Data Interface | Ethernet (LAN) or USB, 50 Hz (standard), higher acquisition rate optional |

| Power Supply | 230 VAC, 1.5 kVA, 50/60 Hz, operating temperature: 5 – 40 °C, humidity: 20 – 80 % |

| Main Tool Mount Interface | R60/30 |

| Required Options for Operation | Handheld controller with force/displacement display, load cell, test tools/fixtures, adapter set, software, PC (current standard), Windows® OS |

Additional Options

- Base table (685 mm height) – conversion to floor-standing model

- Temperature devices (e.g. furnaces, temperature chambers)

- Extensometers: clip-on, long-travel, optical

- Safety enclosures

- T-slot plates for component testing setups

- Electronics expansion up to 7 slots

- Increased testing speed (optional)

Crosshead Options

- Modified moving crosshead

- Load cell shift unit

- Mounting of multiple load cells side by side

- Through-hole for guide bushings (e.g. spring testing)

- Lower fixed crosshead with through-hole

- For tests below the load frame

Compact Machine Design for 250 kN – Maximum Force Without High-Voltage Power

Powerful material and component testing up to 250 kN, operated with a standard power connection (230 V) – ideal for laboratories, quality assurance, and industrial applications.

Technical Data – 250 kN Testing Machine

| Specification | Value |

|---|---|

| Nominal Load | 250 kN |

| Mechanical Design | 2 backlash-free precision ball screws with spindle protection |

| Drive System | AC servo motor |

| Frame Stiffness | 200 kN/mm (including deformation of load cell and tool adapter) |

| Testing Speed | 0.0005 – 175 mm/min (optionally expandable) |

| Crosshead Travel Resolution | < 0.0002 µm |

| Force Measurement Range | Class 1 (optional Class 0.5), 0.1 – 100 % of nominal load depending on the load cell used (per DIN EN ISO 7500-1, ASTM E4) |

| Force Measurement Resolution | 24 bit (±8,388,608 digits) |

| Measurement, Control & Regulation Electronics | Integrated force and travel channels, 3 free slots for analog/digital I/Os, expandable to 7 slots (optional) |

| Data Interface | Ethernet (LAN) or USB, 50 Hz (standard), higher acquisition rates optional |

| Power Supply | 230 VAC, 1.5 kVA, 50/60 Hz, operating temperature: 5 – 40 °C, humidity: 20 – 80 % |

| Main Tool Mount Interface | R60/30 |

| Required Options for Operation | Handheld controller with force/travel display, load cell, specimen grips/test tools, adapter set, software, PC (current standard), Windows® OS |

Additional Options

- Extensometers: clip-on, long-travel, optical

- Safety enclosures for secure test operation

- Electronics expansion up to 7 slots

- Custom test space dimensions & increased testing speeds

Special Frame Features

- Crosshead with through-hole

→ e.g. for guide bushings in spring testing - Lower fixed crosshead with through-hole

→ for testing below the load frame

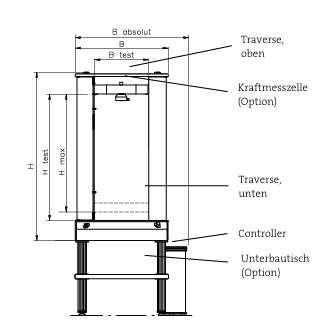

Dimensions / Weight

| Specification | 5 kN | 10 kN | 20 kN | 50 kN | 100 kN | 250 kN |

|---|---|---|---|---|---|---|

| H (Total height) | 1420 mm | 1420 mm | 1420 mm | 1585 mm | 1585 mm | 2250 mm |

| H test (Test space height) | 1080 mm | 1080 mm | 1080 mm | 1170 mm | 1145 mm | 1110 mm |

| H max (Max. crosshead travel) | 1025 mm | 1025 mm | 1005 mm | 1095 mm | 1065 mm | 1030 mm |

| B (Width) | 685 mm | 685 mm | 685 mm | 880 mm | 880 mm | 880 mm |

| B total (incl. control unit) | approx. 1000 mm | approx. 1000 mm | approx. 1000 mm | approx. 1200 mm | approx. 1200 mm | approx. 1200 mm |

| B test (Test space width) | 420 mm | 420 mm | 420 mm | 510 mm | 510 mm | 510 mm |

| T (Depth) | 550 mm | 550 mm | 550 mm | 695 mm | 695 mm | 695 mm |

| Weight | 100 kg | 100 kg | 130 kg | 320 kg | 400 kg | 570 kg |