Compression Set

Compression Set – Reliable Testing of Elastic Materials

Precision, repeatability, and standard-compliant execution

The compression set test is a key method for evaluating the permanent deformation of elastic materials under defined compressive load and elevated temperature. It provides essential data for assessing the recovery behavior and sealing performance—particularly of rubber, elastomers, foams, and sealing materials.

Application Areas

This method is used across numerous industries:

- Automotive industry: Seals, bushings, and damping components

- Medical technology: Silicone seals and foams

- Mechanical engineering & valves: O-rings, molded parts, flat gaskets

- HVAC & electrical industry: Insulation and connector elements

Testing Principle

The specimen is compressed to a defined percentage (e.g., 25%) between two plates and subjected to a specific duration (e.g., 22 h) at an elevated temperature (e.g., 70 °C).

After decompression, the permanent deformation is measured as a percentage relative to the specimen’s original thickness. Evaluation is based on:

- DIN ISO 815-1 / -2

- ASTM D395 Method A / B

- ISO 2285 (for TPE)

Testing Systems by Richard Hess MBV GmbH

For standard-compliant compression set testing, Richard Hess MBV GmbH offers individually configurable solutions:

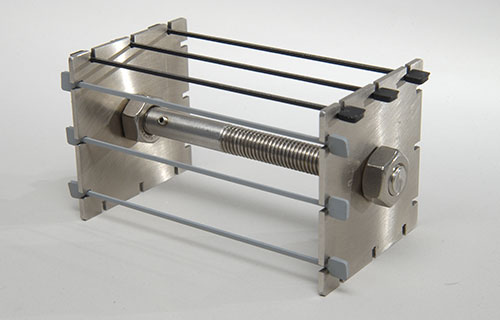

🔹 Precision Compression Fixtures

- Specially designed plate sets ensure consistent compression

- Durable construction for reproducible results

🔹 Temperature Chambers (e.g., SP2700)

- Accurate temperature control from -80 °C to +350 °C

- Optional with automatic nitrogen cooling and door heating

🔹 Data Logging & Evaluation

- Compatible with HessMaster or Hess Soft

- Statistical analysis, protocol generation, and formula editor included

Your Benefits at a Glance

✔ Robust equipment for continuous use

✔ Fully compliant with international standards

✔ Easy operation and safe sample handling

✔ Optional automated temperature control

✔ Compatible with all testing machines of the TMNI, TMCI, and ST series

Want to reliably and accurately test the recovery behavior of elastic materials?

We support you in selecting the ideal test setup—custom-tailored to your standards, materials, and production requirements.

📞 Contact us today – we’ll develop your customized testing solution.