Heat Build-Up Testing Module

Prevent Overheating of Your Rubber Components

A temperature rise in rubber is one of the main causes of material degradation and can ultimately lead to fatigue cracking.

For rubber products such as tires, belts, and vibration dampers, Heat Build-Up (HBU) is a critical design parameter that must be carefully verified and well controlled.

The Metravib Heat Build-Up Module is a powerful extension of the DMA+ Series, designed to accurately analyze the thermal response of rubber compounds under repeated mechanical excitation and advanced test conditions.

Key Benefits:

- Early detection of overheating tendencies in elastomer components

- Realistic test conditions with adjustable parameters

- Quantitative evaluation of heat generation under cyclic loading

- Essential for material selection, design validation, and service life prediction

With the Heat Build-Up Module, Metravib offers a reliable tool for optimizing the thermomechanical performance of your products – ensuring greater safety, durability, and efficiency.

👉 Contact us for more information or to request a personalized consultation!

| Waveform | sinusoidal, haversine, pulse, triangle, square and customized wave forms corresponding to real excitation signal applied to the rubber goods in their daily application |

| Frequency | 0.00001Hz to 1kHz |

| Deformation | up to 12 mm |

| Force | up to 2000N |

| Conditioning temperature | -150°C to 500°C |

Heat Build-Up Testing Module Systems

Testing Under Realistic, Application-Oriented Conditions

With Metravib's Heat Build-Up testing modules, it's possible to go far beyond the standard testing conditions defined by ISO 4666 or ASTM D623.

Unlike the traditional Goodrich Flexometer, which operates solely with a sinusoidal deformation, Metravib’s MULTITEST system offers a multi-harmonic waveform control mode that opens up a wide range of advanced testing possibilities.

Your Benefits with MULTITEST:

- Flexible selection of excitation waveforms:

- Sine, Haversine, Rectangular, Pulse, or even custom-defined signals

- Simulation of real-life load scenarios as encountered in actual applications

- High repeatability and realistic evaluation of heat build-up

- Ideal for optimizing material selection and component design

Whether for tires, seals, or vibration isolators – Metravib’s Heat Build-Up modules allow for testing rubber components under real-world thermal-mechanical stress conditions.

Main Specifications of the Fatigue Heat Build-Up Testing Module

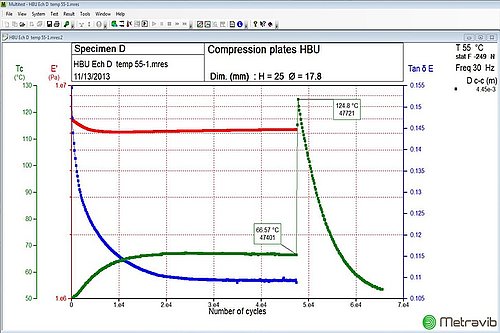

Precise Temperature Analysis Under Dynamic Load

The Fatigue Heat Build-Up Testing Module of the Metravib DMA+ Series is designed for advanced thermomechanical analysis, taking full advantage of the DMA+ system’s wide testing ranges in force, displacement, and frequency, combined with the power of MULTITEST software.

High-Precision Thermal Measurement:

- Specialized specimen holder with heat-insulated compression plates

- Integrated thermal sensor in the upper compression plate for continuous surface temperature monitoring during fatigue testing

- Pneumatically actuated thermal needle probe that penetrates into the core of the specimen at the end of the test to accurately measure internal temperature – without interfering with the dynamic testing process

Flexible Testing Capabilities for Realistic Simulations:

- Multiple loading types: Tension, Shear, Compression

- Compatible with various specimen geometries, including:

- Double-shear sandwich specimens

- Rubber slabs

- Rubber films

Optional Features for Surface Temperature Measurement:

- Infrared temperature sensor for non-contact surface temperature measurement on rubber sheets and films

By combining precise thermal detection, versatile mechanical testing options, and advanced software control, this module provides a customized and powerful solution for elastomer development and quality assurance.