Fatigue Crack Growth Testing Module

Advanced Testing for Quantifying Cracks in Elastomers

Resistance to fatigue, aging, and crack formation is a key concern in the development and application of rubber-like materials, especially in safety-critical industries such as tire manufacturing.

Traditional commercial testing methods typically focus on behavior up to failure, offering limited insight into actual crack propagation.

Since 1999, Metravib has been working closely with leading tire manufacturers to develop a variety of customized testing machines specifically for crack growth analysis.

Based on this extensive experience, Metravib has developed the Fatigue Crack Growth Testing Module – an advanced and efficient testing tool designed to provide the rubber industry and research community with quantitative crack propagation analysis.

Your Benefits:

- Accurate analysis of fatigue-induced crack growth

- Optimized for rubber-like and elastomeric materials

- Valuable for research, development, and quality control

👉 Contact us for more information or to integrate this module into your testing platform.

| Specimen width | 40, 60, 80 mm |

| Specimen height | 6 mm (advised between beads) |

| Specimen type | strip or molded with beads |

| Number of cracks | up to 4 |

| Crack length resolution | better than 2 μm |

| Conditioning temperature | 0°C to 300°C |

| Frequency | 1Hz to 200Hz (main) / 1kHz (harmonics) |

Advantages of the Fatigue Crack Growth Testing Module

Precision, Automation, and Intelligent Integration

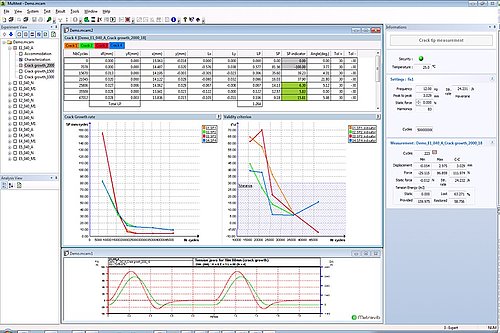

The Fatigue Crack Growth Testing Module is a smart add-on for the Metravib DMA+ Series, significantly enhancing your testing capabilities.

By combining DMA, fatigue, and crack growth testing in a single device, this module offers an exceptionally versatile platform for advanced material characterization.

Key Advantages at a Glance:

- Multifunctional Testing Platform: One device for DMA, fatigue, and crack growth testing

- Flexible Sample Handling: Pure shear specimens (40, 60, or 80 mm wide), molded or rubber strips with specific grips

- Precise Crack Tracking:

- High-resolution CCD video camera

- Motorized scanning across the full specimen width

- Track up to 4 cracks simultaneously

- Exceptional measurement accuracy of better than ±2 µm

- Fully Automated Testing Process:

- No operator intervention required

- Automatic test completion based on predefined criteria:

- Number of cycles

- Stabilization of crack growth rate

- Crack path deviation

- Maximum crack length

This module is specifically designed to deliver accurate, repeatable, and efficient testing for demanding applications—especially in the rubber and polymer research sectors.