Fatigue Testing Machines by Metravib

Reliable Service Life Prediction Through Precise Fatigue Analysis

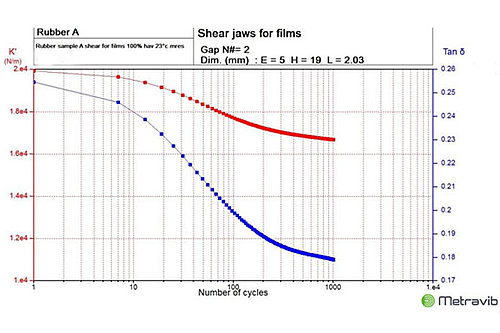

In many industrial applications, materials are subjected to cyclic loading, which often leads to failure mechanisms. As a result, fatigue analysis and lifetime prediction are crucial aspects in research, development, and quality assurance.

The latest models of the DMA+ Series from Metravib offer a powerful solution:

They are based on a high-stiffness, one-piece test frame, providing an extended stiffness and frequency range along with outstanding ergonomics – ideal for precise and repeatable fatigue testing.

Dyna+ Software: Versatile Testing Capabilities

With the powerful Dyna+ software, a wide variety of fatigue tests can be performed – on both material samples and industrial components.

Combined Testing for Maximum Efficiency

The optional DMA module transforms the DMA+ Series into a multifunctional testing platform, allowing fatigue and DMA testing in a single machine – offering maximum flexibility without compromising precision.

👉 Contact us – we’ll be happy to help you find the ideal solution for your testing needs.

| Force | (peak to peak) 300 - 1000 - 2000 Newtons (depending on model) |

| Frequency | from 0.00001 Hz to 1000 Hz |

| Displacement | (peak to peak) 12 mm |

| Thermal chamber | From -150°C to +500°C |

| Building | Highly rigid one-piece mechanical frame |

| High precision measurement | Stiffness, Tan Delta, Young's modulus and shear modulus |

| With only one single instrument | Fatigue, crack growth, DMA, TMA, creep, stress relaxation tests |

| Excitation waveform control | Sinusoidal, haversine, pulse, triangle , square, customized |

| Advanced algorithm | For precise test control |

| Sample analysis | Analysis of material specimens with material-representative size |

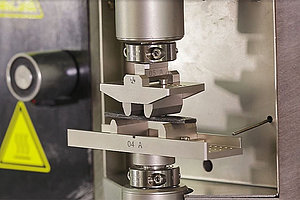

| Configurable for | Traction / compression / bending / shearing |

| Wide selection of specimen holders | For multiple test modes, geometries and dimensions |

| Easily customizable | To meet specific analytical requirements |

Your Benefits at a Glance:

✅ Optimized ergonomic design – for comfortable operation and improved efficiency

✅ Low maintenance – reduces downtime and lowers operating costs

✅ Reduced environmental footprint – sustainable and resource-efficient solution

✅ Optical specimen observation system(optional) – precise visual monitoring during testing

✅ Atmosphere control(optional) – for controlled environmental testing conditions

✅ Humidity control(optional) – ideal for climate-sensitive applications

Features of the DMA+300, DMA+1000 and DMA+2000 series

The DMA+ series instruments rely on the most advanced technologies to achieve high-precision analysis of mechanical properties.

Applications of the DMA+300 / DMA+1000 / DMA+2000

High-Performance Solutions for Research, Development, and Industry

The high-force models of the DMA+ Series offer exceptional versatility – from precise material characterization to realistic simulation of component-level stress conditions.

Typical Application Areas:

✅ Service life prediction of materials under cyclic loading

✅ Fatigue testing of material samples and small to mid-sized components

✅ Testing of composites, polymers, elastomers, and rubber compounds

✅ Fatigue analysis of films and delicate or brittle samples

✅ Simulation of real operating conditions for materials and components

✅ Environmental testing under controlled conditions: temperature, humidity, gas atmosphere, immersion

✅ Heat build-up analysis in coatings and rubber layers

✅ Fatigue crack growth testing under realistic scenarios

✅ Ideal for R&D, quality control, education, and laboratory applications

With the powerful DMA+ Series models, you unlock advanced testing capabilities – precise, flexible, and tailored to industrial needs.

Full DMA Suite Software

Maximum Testing Versatility – All in a Single Machine

With the Full DMA Suite Software, Metravib brings together state-of-the-art features for mechanical material analysis in one versatile testing platform. It allows the combination of DMA and TMA testing, as well as a wide range of static and dynamic measurements – precise, efficient, and fully automated.

Your Benefits with the Full DMA Suite:

✅ Combines DMA (Dynamic Mechanical Analysis) and TMA (Thermomechanical Analysis) in one system

✅ Precise measurement of viscoelastic properties

✅ Determination of glass and secondary transitions

✅ Enables static and quasi-static testing, including:

– Creep, stress relaxation, tension, compression, and more

✅ Long-term creep prediction for advanced lifetime assessments

Whether in research, development, or quality control – the Full DMA Suite enhances your testing depth and saves valuable resources by integrating multiple testing methods in one machine.

👉 Learn more about the benefits of this all-in-one software solution – we're here to help!